Don't hesitate to contact us

+91 9751523891

info@igaengineering.com

11 kasthuri nagar, KN palayam, Vadavalli, Coimbatore.

Vent Silencers

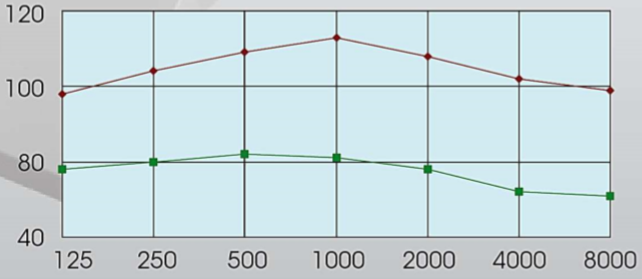

Exhaust fluid silencers under pressure are usually employed to check noise coming from the steam, air, natural gas, azote, oxygen and other gaseous fluids exhaust to the atmosphere with a pressure higher than the atmospheric pressure.

These equipments are usually set up downstream interception valves, which connect a tank or a piping holding the fluid under pressure and the atmosphere.

The opening of these valves generally causes a sonic outflow running, that is a critical pressure drop and produces an extremely high sound level, not easy to tolerate.

The application of the silencer before the outflow to the atmosphere changes the exhaust conditions of the line, introduces a gradual and controlled counterpressure and so modifies the relation among the pressures.

So a gradual expansion of the fluid exhausted is possible. The atmospheric conditions are gradually reached and the sound level produced is highly reduced.

Technical Features

The silencers are made of a cylindrical, carbon or stainless steel, external body, where the expanders battery takes place. Through it the fluid undergoes a gradual pressure reduction. When the fluid-dynamic conditions of the process don’t allow high levels of counter pressure produced through the silencer, avoiding the maxim acoustic efficacy, another attenuation phase is linked together to the expansers battery inside the silencer.

It’s a sound absorption silencer type, which produces a further sound attenuation through absorbing of energy of the sound-waves in a deadening material.

DESIGN DATA

– Capacity : 30 t/h

– Temparature : 230°C

– Pressure : 17 bar

– counterpressure : 3 bar

without Compromising the exhaust and safety conditions of the vent, the setting up of the silencer has allowed a reduction of the global sound level of 30dB(A).

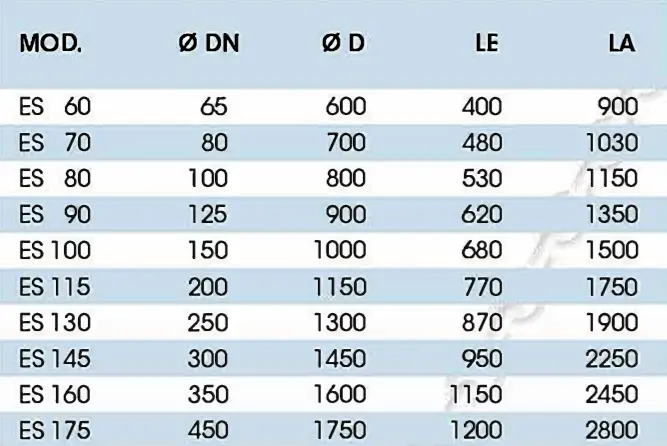

SILENCERS SERIES ES

DIMENSIONAL FEATURES

The lengthes LE and LA correspond to silencers series ES only with an expansion attenuation battery or to silencers with an absorption attenuation phase, respectively

DATA FOR THE DESIGN

To design the silencer properly, the customer should convey the following data:

-type of fluid discharged

– type of setting up planned (vertical/horizontal)

– capacity discharged

– fluid temperature upstream valve

– fluid pressure upstream the valve

– counterpressure limit

– residuai sound level required

– measure point of the residuai sound level

– high of the silencer compared with the measure point.

ACCESSORIES

lf required, the silencers series ES can be delivered with the following accessories:

– inlet flanges counterfla nges

– cover rain

– expansion joint

– support structures